As the textile industry continues to demand higher production efficiency, better product quality, and more sustainable practices, large circular knitting machines have become a cornerstone of textile production. These machines integrate advanced technologies, not only improving production efficiency but also driving innovations in knitting processes. From intelligent control systems to automated production lines, large circular knitting machines are evolving toward greater efficiency, precision, and sustainability.

1. Industry Overview of Large Circular Knitting Machines

Large circular knitting machines are widely used in the production of high-quality fabrics, especially for manufacturing products like socks, activewear, and underwear. Compared to traditional small knitting machines, large circular knitting machines offer significant improvements in speed, product quality, and automation levels.

In global textile production, high-speed, automated circular knitting machines have become the standard. These machines efficiently handle a variety of yarn types, including natural and synthetic fibers. Not only can they quickly knit high-quality fabrics, but they also allow flexible adjustments to fabric density and texture, catering to the market’s demand for diverse products.

2. Cutting-edge Technologies: The Integration of Intelligence and Automation

a. Intelligent Control Systems

Modern large circular knitting machines feature advanced intelligent control systems, integrating IoT (Internet of Things) technologies and big data analytics to monitor machine status and production data in real-time. These systems not only allow remote control of the machines but also provide real-time production feedback, enabling operators to make adjustments and optimizations. This improves efficiency and reduces downtime caused by machine failures.

b. Automated Textile Production Lines

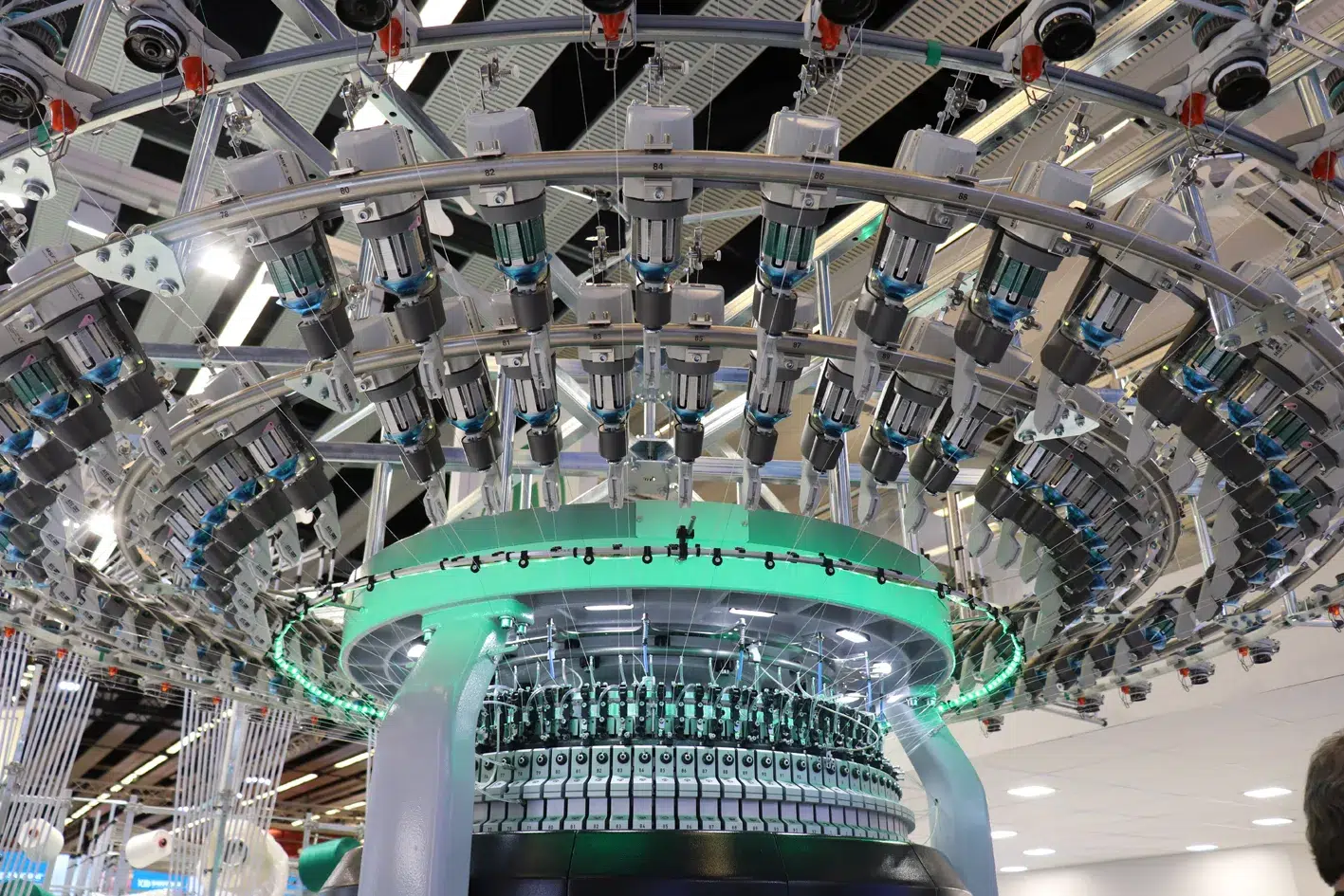

Automation is another prominent feature of large circular knitting machines. Many manufacturers now offer fully automated circular knitting production lines. With features like automatic yarn threading systems, automatic winding, and automatic tension adjustment, these machines significantly reduce the need for manual intervention, improving overall production efficiency. Machines equipped with sensors can monitor yarn tension and fabric density, automatically adjusting the knitting process to ensure consistent high-quality output.

c. 3D Knitting Technology

With the development of 3D knitting technology, some modern circular knitting machines are now capable of producing three-dimensional fabrics. This technology allows the machines to create multi-layer structures or directly produce fabrics with a 3D effect during the knitting process. It is particularly suitable for the high-end market, including sports equipment, automotive seat fabrics, and medical textiles, enabling innovative designs and enhanced comfort.

3. Real-World Applications: Large Circular Knitting Machines in Global Textile Production

a. High-efficiency Sock Production

In sock production, large circular knitting machines are widely used to produce high-quality, long-lasting socks. Modern circular knitting machines ensure consistent stitch quality for every pair of socks through precise control systems, while automatic yarn threading systems reduce manual labor, improving efficiency across production lines. Additionally, the automatic adjustment features of these machines can optimize the knitting process based on the yarn’s tension and fabric density, ensuring stable and high-quality output.

b. High-performance Activewear Fabric Production

Activewear fabrics have high demands for comfort and functionality. Large circular knitting machines are used to produce a variety of performance fabrics, such as those with moisture-wicking, breathability, and UV protection properties. By utilizing intelligent control systems, these machines can precisely adjust knitting parameters, ensuring consistent quality and enabling quick adaptation to the ever-changing demands of the market.

c. Underwear and High-end Fashion Fabric Production

High-end fashion and underwear production require fabrics that are soft and of the highest quality. Large circular knitting machines can produce fine, soft fabrics at high speeds, meeting the demands of premium markets. Some machines even incorporate 3D knitting technology, directly producing fabrics with intricate three-dimensional patterns, meeting the needs of fashion designers for innovative fabric solutions.

4. Ongoing Innovation: Energy Efficiency and Sustainability

As global environmental regulations become stricter, energy efficiency and sustainability have become essential directions in the development of large circular knitting machines. Many newer models incorporate high-efficiency motors and variable frequency drive systems, significantly reducing energy consumption. By optimizing machine drive systems and knitting structures, these machines offer lower energy usage without compromising production efficiency.

Moreover, an increasing number of machines are incorporating eco-friendly materials and water-saving technologies, reducing wastewater and air emissions during the textile production process, and meeting international environmental standards. These innovations not only help manufacturers reduce operational costs but also contribute to the industry’s shift toward greener production.

5. Conclusion

Large circular knitting machines are evolving toward greater intelligence, automation, and sustainability. As technology continues to advance, these machines are not only providing higher production capabilities but also addressing the growing demand for complex, high-end fabric products. With the integration of intelligent control systems, 3D knitting technology, and automated production lines, large circular knitting machines are fundamentally changing the way textile production operates.

Whether enhancing production efficiency, lowering costs, or meeting environmental challenges, modern large circular knitting machines offer strong technological support to textile manufacturers. As technology continues to evolve, we can expect these machines to play an even greater role in driving the future of more intelligent, sustainable textile production.

Why Choose KING KNIT?

Expertise: Years of experience in sock machine manufacturing, continuously innovating to meet market needs.

Quality Assurance: Stringent quality testing ensures your machines are ready for immediate production.

Customization Options: Tailor our equipment to fit your specific production requirements.

Customer Satisfaction: Dedicated support from setup to ongoing maintenance, ensuring smooth operations.

Choose KING KNIT to elevate your sock production process!

Single jersey circular knitting machine

Single jersey circular knitting machine

Single jersey computerized jacquard knitting machine

Single jersey computerized jacquard knitting machine

Double Jersey circular knitting machine

Double Jersey circular knitting machine

Rib tansfer electronic jacquard knitting machine

Rib tansfer electronic jacquard knitting machine

Double electronic jacquard circular knitting machine

Double electronic jacquard circular knitting machine

Double jersey computerized acquard circular knitting machine

Double jersey computerized acquard circular knitting machine

Double jersey mini jarquard knitting machine

Double jersey mini jarquard knitting machine

Reverse or face side terryknitting machine

Reverse or face side terryknitting machine

Terry electronic jacquard knitting machine(2/3ways)

Terry electronic jacquard knitting machine(2/3ways)

High speed open width double jersey knitting machine

High speed open width double jersey knitting machine

Automatic Linking intelligent socks knitting machine

Automatic Linking intelligent socks knitting machine

computerized plain socks knitting machine

computerized plain socks knitting machine

Double cylinder sock knitting machine

Double cylinder sock knitting machine

Single jaquard scarf&hat knitting machine

Single jaquard scarf&hat knitting machine

Interested in the machinery

Based in South Africa,North west province, Vryburg town.

Interested in your kingknit machinery